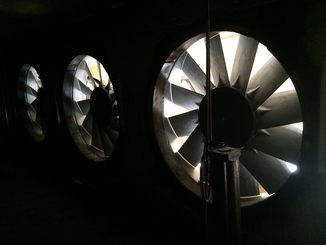

Fans

Dry kilns are responsible for about half of the electricity consumption at a sawmill.

Make sure to have air in the system.

The circulating air in the kiln has several tasks. It transfers energy to the timber, used to evaporate water. It also removes the evaporated water from the wood surface.

As the air blows through the heating coils is heated. Evaporating water requires energy and that energy is taken from the air. Therefore, the temperature drops in the air as it moves through the timber stacks.

As one of the parameters of the drying force is the difference between the dry and wet bulb, the psychrometer difference, the drying power decreases as it passes through the timber.

The more air that circulates, the lower the temperature drop and, in other words, the more even the drying result.

The so-called drying power is not only dependent on the difference between dry and wet bulb temperature, it also varies with specific temperature level. Even the air velocity in the spaces in between the timber has a very large impact on water evaporation from the wood surface. The heat transfer coefficient is proportional to the air speed. And the so very important temperature drop, which determine the uniformity of the drying in a drying chamber, is directly proportional to the effective amount of circulation air and water evaporation.

A properly sized kiln has a fan system that is tuned in terms of both air volume and resistance through the timber and the radiators.

Should you replace existing fans or should you upgrade? Talk to us first!